Densen Customized Stainless Steel Meat Grinder Screw Mincer Meat Grinder Parts Meat Grinder Bades

Basic Info

| Model NO. | Customized |

| Casting Method | Thermal Gravity Casting |

| Process | Investment Casting |

| Molding Technics | Gravity Casting |

| Application | Instrument Accessories |

| Material | 304 |

| Surface Preparation | Polishing |

| Surface Roughness | Ra1.6 |

| Machining Tolerance | +/-0.15mm |

| Standard | GB |

| Certification | CE, ISO 9001:2008 |

| Power Source | Electric |

| Type | Meat Grinder |

| Customized | Customized |

| Automatic Grade | OEM |

| Voltage | OEM |

| Weight Ranges | 8g-100kg |

| Tolernace | Controlled by ISO 8006 CT4-6 |

| Low MOQ | 10-100 PCS |

| Application Scope | Food Machinery Parts |

| Finishing | Mirror Polishing, Electrical Polishing |

| Transport Package | Wooden Case,Plywood Case,PE Film,etc.up to Custome |

| Specification | as per customers′ specifications and drawings |

| Trademark | Densen Customized |

| Origin | China |

| Production Capacity | 150000 Piece/Pieces Per Month |

Product Description

Densen customized Stainless steel Meat Grinder Screw Mincer Meat Grinder Parts Meat Grinder BadesOEM Stainless Steel Feedscrew1. Grade: over 300 grades

2. Size: 2mm-1000mm

3. Standard: AISI, ATSM, UNI, BS, DIN, JIS, GB etc

4. Certification: ISO9001, IATF 16949, CE/PED, RoHS

Description | Spare parts for meat grinders meat grinding machine |

Type | Customized |

Application | meat grinder, meat mincer, food processing machinery |

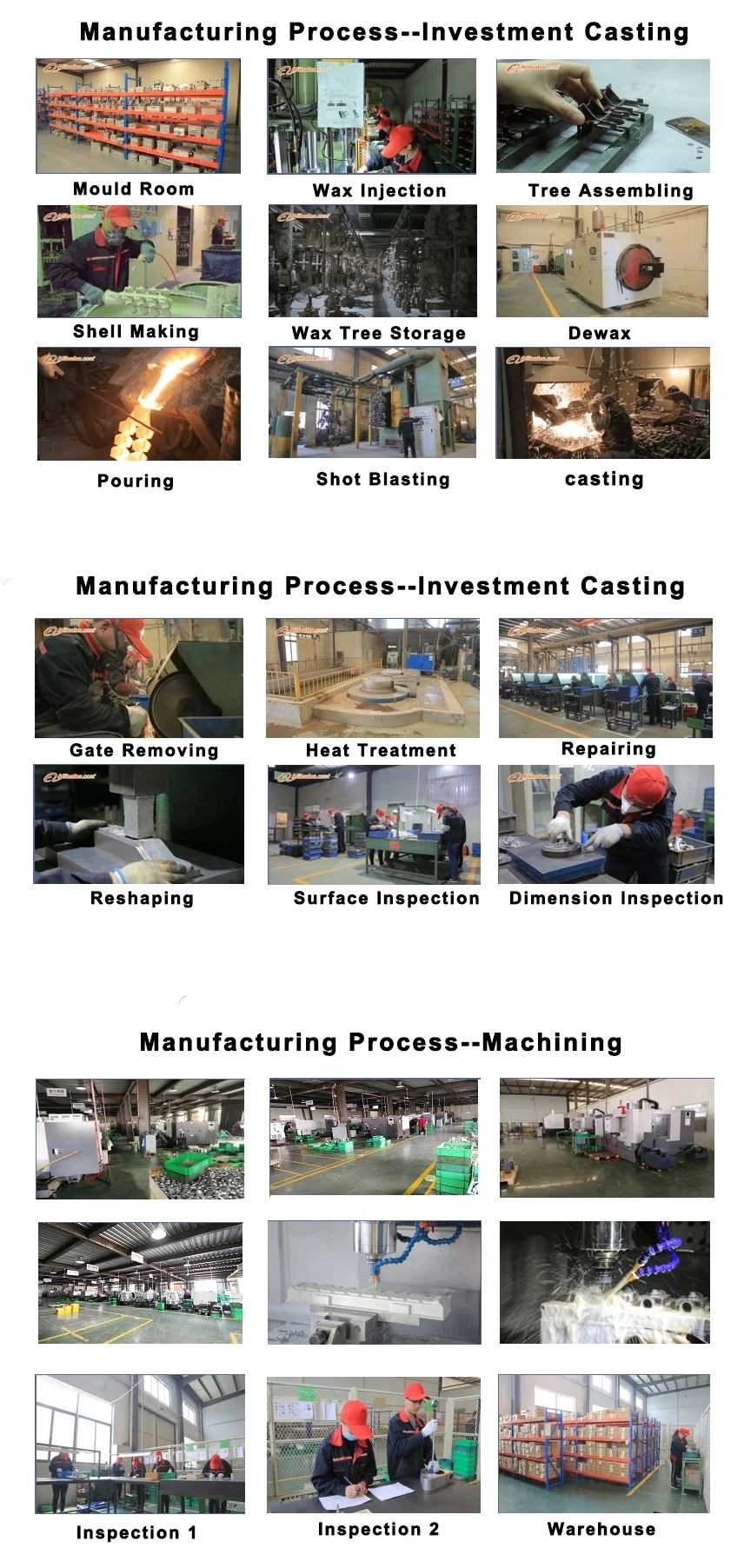

Processing | Precision investment casting and CNC machining + polishing |

Material | Stainless steel,duplex stainless steel,carbon steel , alloy steel |

| Weight Ranges | 8g-80kg |

Surface Treatment | Polishing ,electrogalvanizing, phosphorization,powder spraying |

Design Support | Pro-E, UG,SolidWorks,AutoCad, PDF |

Quality Control | Material, Dimension,Performance,inside defects,Balance test |

Standard | ASTM,DIN,JIS,ISO,GB standards |

Stainless Steel Meat Grinder parts , silica sol precision casting ,never rust ,high cnc machining quality

Process: Stainless Steel Precision Silicon Sol Casting + Precision Machining+Polishing

Main Use: Used in Commerical Food Machinery Parts

China Stainless Steel Meat Grinder parts manufacturers and suppliers - wholesale high quality Stainless Steel Meat Grinder parts made in China here, all with ISO certificates. Also, customized service is available.

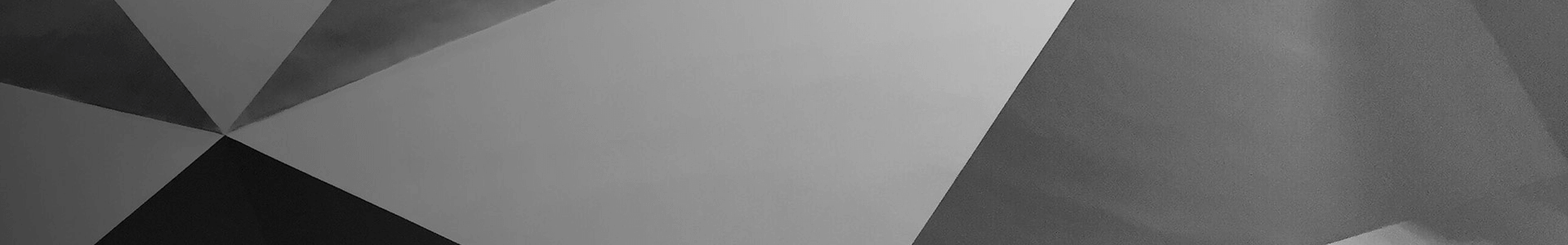

Production Process

1.Casting Mould for stainless steel Meat Grinder parts

2.Stainless Steel Meat Grinder Casting

3.Casting Shell of Meat Grinder parts

4.Casting Blank and Machining of Stainless Steel Meat Grinder parts

Company Information

Shenyang New Densen Casting and Forging Company is the sales company of Shenyang Densen Group of Companies. Features of New Densen simply summarized as below:

1. Trusted supplier of steel, iron & non-ferrous components;

2. Extensive documented quality program in place.

3. Castings, forgings, stampings, machining, welding & fabrication services.

4. 9 related factories, over 50 joint-venture sub-contractors.

5. 25+ years of manufacturing experiences, 10+ years of exporting experience

6. 100% of products sold to overseas customers.

7. 50% of customer base is forturne 500 companies.

Processing support

3rd Party Inspection:

New Densen worked as 3rd party inspection center besides its sister factories or sub-contractors' self inspection, Offers process inspection, random inspection and before delivedry inspection services for material, mechanical, inside defects, dimentional, pressure, load, balance, surface treatment, visual inspection and test. Weekly project follow-up report together with pictures and videos, full quality inspection documentation available.

New Densen also designed as 3rd party inspection representative for several customers when their products made by other suppliers.

FAQ

Frequently Asked Question

1. Are you a manufacturer or a trader?We are manufacturer AND trader, as we have own factories and also long term friendly cooperated sub-contractors. That is why we could provide one-stop service to worldwide customers.

2. What can you do for customer ?

One Stop Service1).Manufacturing and supply various machinery parts.2). Technical analysis and design 3).Factory audit, on-site production supervision, in-time feedback, pre-shipment quality inspection

3. How could you commit the product quality

1) all our factories were ISO certified.

2) more than 50% of New Densen's products were sold to worldwide top 500 companies which located in North American,

Western Europe, and Japan.

3) New Densen's QC engineers will do on-site supervision and before EX-work quality inspection.

New Densen will issue inspection reports for customers' approval before EX-work. New Densen will be

responsible for its reports and every parts no matter how long sold to customers.

4. What is your payment term?

1) Pattern and tooling: 50% prepaid as order deposit; balance 50% paid within 10 days after samples approved.

2)Sample : 50% prepaid as order deposit; balance 50% paid within 10 days after samples approved.

3)Product: 30% prepaid as order deposit;70% paid before EX-work.

If samples can't be approved by customers and no need to redo new samples, deposit will be returned to customers.

Welcome customer place order with us through credit system (Trade Assurance), to get alibaba's credit guarantee.

5. How long shall we get the quotation?

1-3 working days for simple products; 3-5 working days for complicated products